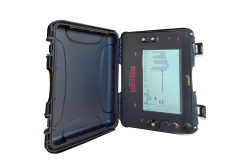

Flaw Detector

The 300 series Flaw Detector are used to test the internal structure of solid materials such as: concrete, graphite, granite, sandstone, marble, as well as liquids and gases. It is used to measure building elements that require high safety parameters.

The Flaw Detector works by measuring the passage of an ultrasonic wave of a certain frequency and high energy through the tested material. A physical phenomenon was used, consisting in changing the speed of propagation of a mechanical wave in an environment of variable density.

If the structure of the tested material contains discontinuities, cracks, wave deflection and changes in the time of passage of the acoustic wave occur.

The receiving head of the concreteoscope records the moment of passage of the ultrasonic wave generated by the transmitting head. The measurement of the wave transit time is shown on the display of the device. Performing the measurement does not change the structure, damage or destruction of the material.

Our Flaw Detector are made of a very durable, durable housing, which creates good working conditions even in difficult weather conditions. The temperature range in which the device can operate ranges from -10 ° C to 40 ° C. The device uses energy-saving electronic systems, modern Li-lon batteries, and is extremely light, allowing for long-term measurements.